Tips On How To Ensure Versatility Of Your Logo Design

A company’s logo design is used on various marketing strategies. A logo appears in various sizes ranging from as big as billboards to tiny ones like on a business card, pens and stickers. Therefore, a logo must be scalable. It should also appear impressive in both color as well as black & white versions.

All types of businesses use logos as an effective marketing tool. People usually recall a business by seeing its logo on products and on advertisements. We can say that logos take business messages to the people and help the companies in converting the viewers into potential buyers.

However, success of a logo design largely depends on its quality of being versatile. This means that the logo must look equally great on all sizes of products. So, the logo must look impressive not only on big scales of large billboards to the size of a stamp. The logo must not lose its shape, size, colors, fonts, and other vital elements in all sizes. This is one of the basics of logo design.

A logo is printed on larger billboards or on fairly smaller advertising products such as pens, stickers, rubber stamps and business cards. In addition, the same logo must also look impressive on pixel based media such as websites and web banners. Business owners can use such versatile logos on a wide range of ads and products or services. Clearly, the businesses should be able to reproduce the logo in its varied sizes.

Versatility is one of the most essential quality of a good logo design. In the 21st century, brands are highly visible. They are exposed to a wide range of media. Most of the brands are actively projected on social media pages. This means that a logo should appear great on all the social media such as Facebook, Twitter, Instagram.

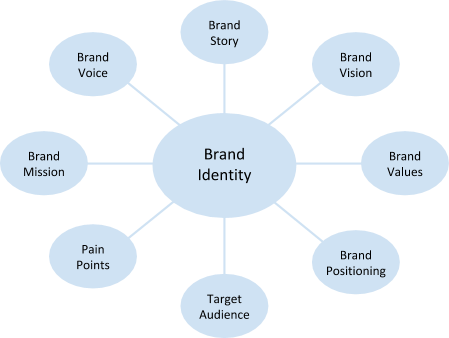

Another reason why your logo should be versatile is that it helps create your brand identity. So, a logo should look good when printed on the top of a letterhead, business card, mobile app icon, etc.

A versatile logo is cost-effective. It saves you money and time as you do not necessarily have to create separate logos for different media ads and products. Since, the same logo goes for all ads and promotion ranging from large billboards and smallest stamp size ads; you get to save a considerable amount. Additionally, your printing cost decreases manifold when you use fewer colors in the logo.

Here Are Some Tips To Create A Versatile Logo

01. Consider The Details

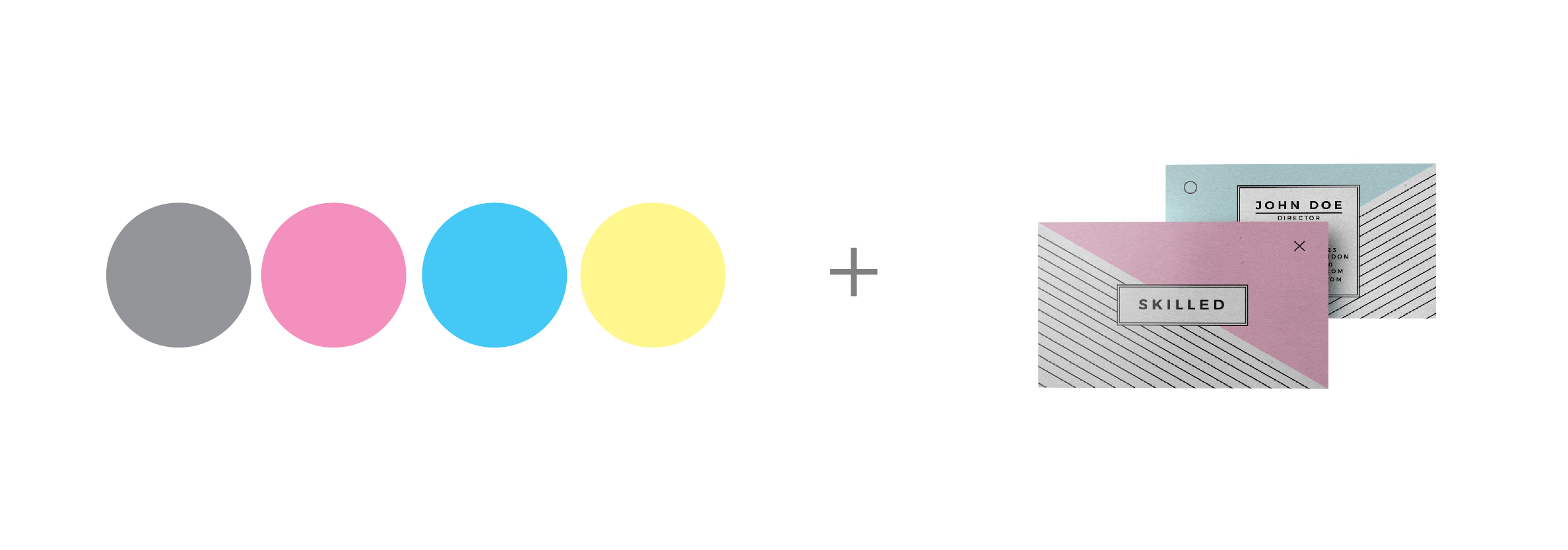

While designing your logo, consider how much detail should go in it. The details of lines, colors, fonts etc. are necessary to convey the business message. But too many details may create printing troubles for a logo.If the details are minute such as delicate or skinny lines and too many colors, then these may disappear when printed. These details may appear as broken shapes when printed in small sizes. So, it is advisable to keep only fewer details that are extremely necessary for the logo.

A logo with fewer details will save your production cost of graphic design items. For example, your overall cost of a business card design will be lower to produce it if the logo that you print on the card is also a simple design.

02. Pay Attention To The Space

If a logo design has the white space, or negative space, it must be created carefully. The white space between the two elements should be consistent. This means that the space should not be too close as it may lead to elements overlapping each other when the logo is printed. And if the space distance is too big, the viewers may not find an association between the elements and the logo may fail to communicate well with the viewers.

03. Use Gradients SelectivelyOpt for gradients only when they can contribute to the overall quality and appeal of the design. Avoid choosing too light tints as such tints usually disappear when printed and the logo appears in white color scheme only.

Do not necessarily opt for too dark tints as they may appear too solid and patchy when printed. In fact, too dark tints create a muddy look for the logo when printed on a newspaper. Take note of the fact that some reproduction processes do not accommodate use of gradients very well.

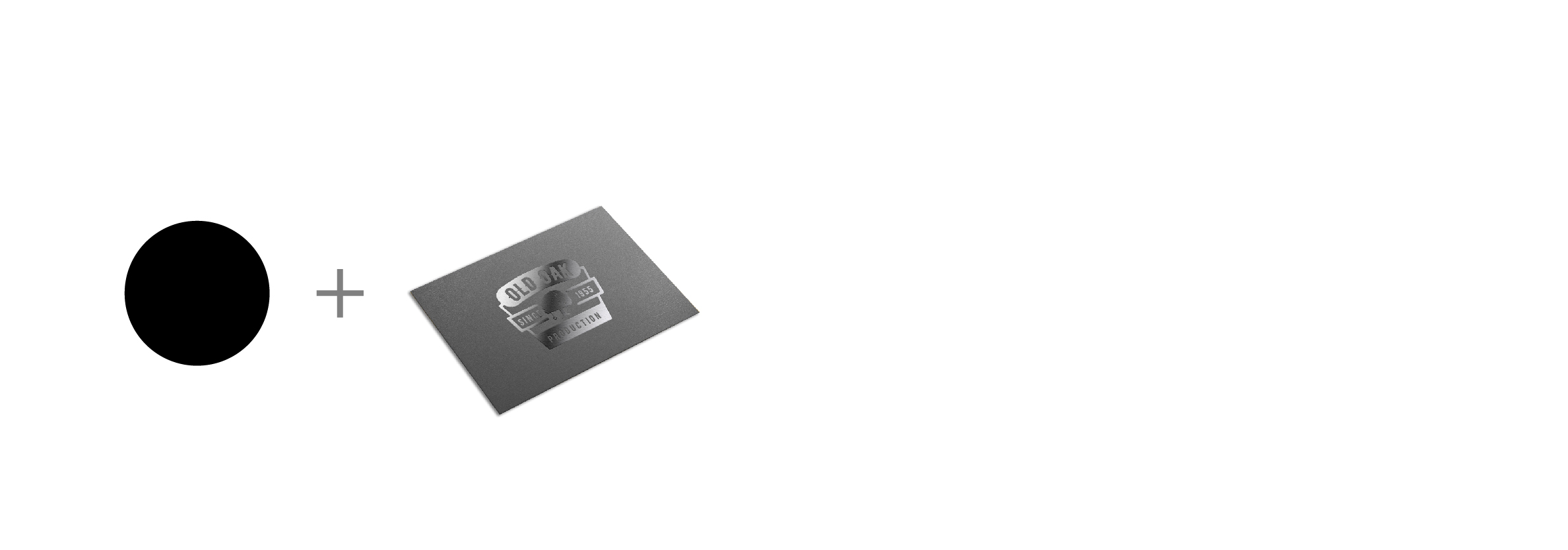

04. Create Logo Without Colors

Another sign of a versatile logo is that it appears impressive in both colors and without colors. This is because a logo is printed on newspapers, magazines, faxed copies, etc. in black and white. So, the logo must retain its uniqueness when printed without colors. This will ensure better logo and brand identity design of the business symbol.

A trick to create a versatile logo that looks impressive in black and white is to create it first without colors. When designing the logo, first create it in black and white only. It is only when you are satisfied with the design that you should fill colors in it. As a graphic designer, you should take a logo and get approval. Then, incorporate colors after getting the approval.

Read more of our informative blogs at:http://store.printcafeli.com/blog/Print_Cafe_Blog.html