Affordable Flyer Printing Services

Just Around the Corner:

Your Guide to Cheap Flyer

Printing Near Me

Affordable Flyer Printing Services Just Around the Corner: Your Guide to Cheap Flyer Printing Near Me

Are you looking for affordable flyer printing services near you? Look no further! In this comprehensive guide, we will walk you through the process of finding cheap flyer printing services that are conveniently located in your area. Whether you need flyers for a business promotion, event, or any other purpose, we’ve got you covered.

At the Print Cafe of LI, we understand the importance of cost-effective marketing solutions. That’s why we specialize in providing high-quality flyer printing services at competitive prices. With our state-of-the-art printing technology and a team of experienced professionals, we guarantee exceptional results that will make your flyers stand out from the crowd.

Our convenient location makes it easy for you to access our printing services in Lynbrook, New York. Plus, our quick turnaround time ensures that you receive your printed flyers in no time. Say goodbye to the hassle of searching for printing services far away or waiting weeks for your order.

Don't settle for subpar flyer printing. Trust the Print Cafe of LI for affordable, high-quality, and conveniently located services. Contact us today to learn more and get started on your flyer printing project.

Benefits of Flyer Printing for Businesses

Flyer printing offers numerous advantages for businesses seeking to enhance their marketing efforts. One of the primary benefits is the cost-effectiveness of flyers as a promotional tool. Unlike other forms of advertising, such as television or digital ads, flyers can be produced at a fraction of the cost while still reaching a wide audience. This affordability allows businesses, especially small and medium enterprises, to allocate their marketing budgets more effectively without compromising on visibility. By investing in flyer printing, companies can generate a significant return on investment through increased foot traffic and sales.

Another key advantage of flyer printing is its versatility. Flyers can be used for various purposes, including promoting special events, launching new products, announcing sales, or even simply raising brand awareness. They can be distributed in different ways, such as door-to-door, at local events, or placed in high-traffic areas. This flexibility enables businesses to tailor their marketing strategies to suit their specific needs and target audiences. Whether aiming for a specific demographic or a broader market, flyers can be customized to convey the right message.

Finally, flyers provide a tangible marketing solution that digital ads cannot replicate. In an age where consumers are bombarded with online advertisements, physical flyers can stand out and create a lasting impression. People are more likely to remember a well-designed flyer that they can hold in their hands compared to a fleeting online ad. This physical presence can lead to increased engagement and interest in a business, making flyer printing a powerful tool for building brand recognition and customer loyalty.

Factors to Consider When Choosing Flyer Printing Services

When selecting flyer printing services, several factors come into play that can significantly impact the final product and overall satisfaction. One of the most important considerations is the quality of the printing. High-quality printing ensures that colors are vibrant, text is clear, and images are sharp. Businesses should inquire about the types of printers and materials used by the printing service to guarantee that their flyers will reflect a professional image. Additionally, checking samples of previous work can provide insight into the quality of the service.

Pricing is another critical element to take into account. While affordability is a priority, it is essential to balance cost with quality. Some printing services may offer lower prices but at the expense of quality, which can ultimately harm a business's reputation. It’s advisable to request quotes from multiple printing services and compare what is included in the price, such as paper type, size options, and finishing touches. Understanding the full scope of costs will help businesses make informed decisions without unexpected expenses.

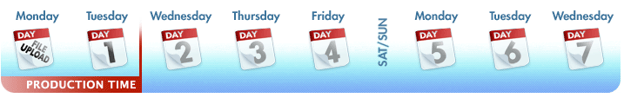

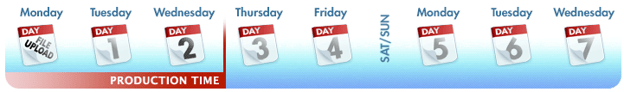

Customer service is equally vital when choosing a flyer printing service. A responsive and knowledgeable team can make the printing process smoother and more enjoyable. Businesses should assess whether the printing service provides clear communication, assistance with design options, and support throughout the ordering process. A reliable printing service will also offer quick turnaround times and the flexibility to accommodate last-minute changes, ensuring that businesses receive their flyers when they need them.

How to Find Cheap Flyer Printing Services Near You

Finding affordable flyer printing services in your area can be a straightforward process if you know where to look. One of the best starting points is local business directories and review websites. Websites like Yelp or Google Maps allow users to search for printing services within a specific location, providing helpful reviews and ratings. This not only helps in identifying nearby printing companies but also gives insight into the experiences of other customers, ensuring that you choose a reputable service.

Another effective approach is to leverage social media platforms. Many local businesses actively promote their services through Facebook, Instagram, and Twitter, making it easier for potential customers to discover affordable options. By following local business pages and joining community groups, you can stay updated on promotions, discounts, and special offers on flyer printing services. Engaging with local businesses on these platforms can also lead to valuable recommendations from other community members.

Networking with fellow business owners can also provide insight into finding cost-effective printing services. Attend local business events, trade shows, or chamber of commerce meetings to connect with other entrepreneurs who may have experience with flyer printing services. They can share their recommendations and may even have contacts that could lead to exclusive deals. Building relationships within your community can open doors to affordable services that may not be widely advertised.

Comparing Prices and Quality of Different Flyer Printing CompaniesWhen it comes to flyer printing, comparing prices and quality among various printing companies is crucial to ensure that you get the best value for your investment. Start by gathering quotes from multiple printing services, ensuring that the specifications are consistent across the board. This means comparing similar sizes, paper types, and quantities to get an accurate representation of pricing. Some companies may offer bulk discounts, so it’s worth inquiring about pricing tiers based on quantity.

Evaluating the quality of the printed flyers is equally important. As price alone does not dictate quality, it is advisable to ask for samples from the printing companies you are considering. Look for details such as color accuracy, clarity of text, and overall craftsmanship. Pay attention to the paper quality as well; thicker, more durable paper can enhance the perception of your brand and the effectiveness of your flyers. Quality materials can significantly impact how your flyers are received by your target audience.

In addition to price and quality, consider the services offered by the printing companies. Some may provide design assistance, while others might offer additional features like folding, cutting, or custom finishes that can enhance the final product. A company that provides more comprehensive services may justify a slightly higher price due to the added value. Ultimately, balancing cost with quality and the range of services available will help you make an informed decision that aligns with your business goals.

Tips for Designing Effective Flyers

Creating an effective flyer requires careful thought and planning to ensure that the final product captures attention and conveys the intended message. One of the most crucial tips for designing flyers is to keep the layout clean and organized. Use a clear hierarchy of information, making it easy for the reader to navigate through the content. Use headings, bullet points, and ample white space to avoid overwhelming the audience with too much text. A well-structured flyer allows key messages to stand out and makes it easier for potential customers to absorb the information quickly.

Color selection plays a significant role in flyer design as well. Choose colors that align with your brand identity while also considering the psychology of colors. For instance, blues can evoke trust, while reds can create urgency. Using contrasting colors for text and background will enhance readability and draw attention to important details, such as calls to action. However, it’s essential to strike a balance and not overuse colors, which can lead to visual chaos.

Images are another vital element in flyer design. High-quality visuals can enhance the overall appeal and effectiveness of your flyer. Ensure that any images used are relevant to the content and resonate with the target audience. Additionally, avoid cluttering the flyer with too many images; instead, select a few strong visuals that support your message. Including a clear call to action—such as “Visit us today!” or “Call now for a discount!”—is essential for encouraging potential customers to take the next step.

Common Mistakes to Avoid in Flyer Printing

When it comes to flyer printing, there are several common mistakes that businesses often make, leading to ineffective marketing materials. One of the most frequent errors is neglecting to proofread the content thoroughly. Typos, grammatical errors, and incorrect information can undermine the professionalism of your flyers. Always take the time to review the text multiple times and consider having a second pair of eyes look it over before sending it to print. A well-crafted flyer demonstrates attention to detail and can significantly impact your brand's image.

Another common mistake is failing to define a clear target audience. Without understanding who you are trying to reach, your flyer may not resonate with potential customers. Tailoring the content, language, and visuals to suit your target demographic is essential for creating an effective flyer. Conduct market research to identify your audience's preferences and pain points, which will guide the design and messaging of your flyer, ensuring it speaks directly to their needs.

Additionally, businesses often overlook the importance of a strong call to action (CTA). A flyer should not only inform but also motivate the reader to take a specific action. Whether it’s visiting a website, calling a phone number, or attending an event, a clear and compelling CTA is crucial. Ensure that the CTA stands out visually and is easy to follow. Without a strong CTA, even the most beautifully designed flyer may fail to drive the desired response from potential customers.

Additional Services Offered by Flyer Printing Companies

Apart from standard flyer printing, many printing companies offer a range of additional services that can enhance the overall marketing strategy for businesses. One valuable service is graphic design assistance. Many printing companies employ skilled designers who can help create eye-catching flyers from scratch or refine existing designs. This service can be particularly beneficial for businesses lacking design expertise, ensuring that the final product is both professional and appealing.

Another additional service that some flyer printing companies provide is mailing services. For businesses looking to distribute their flyers widely, utilizing mailing services can save time and effort. These companies can handle the printing, addressing, and mailing of flyers directly to targeted lists, streamlining the marketing process. This convenience allows businesses to focus on their core operations while still reaching potential customers effectively.

Finally, many flyer printing companies offer value-added services such as custom finishes, folding options, and specialty papers. These services can help businesses differentiate their flyers in a crowded marketplace. For example, incorporating glossy finishes or unique paper textures can elevate the perceived quality of the flyers, making a more significant impact on the audience. Exploring these additional services can help businesses create more compelling marketing materials that stand out and drive engagement.

Customer Reviews and Testimonials of Flyer Printing ServicesWhen choosing a flyer printing service, customer reviews and testimonials can provide invaluable insight into the quality and reliability of the company. Positive reviews often highlight aspects such as exceptional customer service, quick turnaround times, and high-quality printing. Reading through testimonials can help potential customers gauge the experiences of others and build confidence in their decision. Look for consistent themes in reviews to identify strengths and weaknesses of various printing companies.

On the other hand, negative reviews can serve as a warning. If multiple customers report similar issues—such as poor print quality, missed deadlines, or unresponsive customer service—it may be a red flag. Consider the overall rating of the company while also paying attention to the context of reviews. Sometimes, companies may have a few negative reviews but still maintain a high overall rating, indicating that they have successfully resolved issues and learned from past mistakes.

In addition to online reviews, reaching out to personal networks for recommendations can also be beneficial. Friends, family, or business colleagues may have firsthand experience with local flyer printing services and can provide honest feedback. These personal connections can lead to finding trusted printing partners that may not be prominently advertised online. Overall, gathering customer reviews and testimonials is an essential step in selecting a reliable flyer printing service that meets your needs.

Conclusion and Final Thoughts on Affordable Flyer Printing Services Near You

In conclusion, finding affordable flyer printing services near you is a practical and effective way to enhance your marketing efforts without breaking the bank. By understanding the benefits of flyer printing, considering crucial factors when selecting a service, and leveraging the insights of customer reviews, businesses can make informed decisions that align with their goals. The key is to balance cost with quality, ensuring that the final product effectively communicates the intended message and resonates with the target audience.

Designing impactful flyers is also vital to the success of your marketing campaigns. By avoiding common mistakes and utilizing additional services offered by printing companies, you can create flyers that stand out and drive engagement. Remember to keep your design clean, use high-quality visuals, and include a compelling call to action to maximize the effectiveness of your flyers.

As you embark on your flyer printing journey, stay persistent in your search for the right printing partner. With the right approach, you can find affordable, high-quality flyer printing services just around the corner, ready to help you promote your business effectively. Embrace the power of flyers as a marketing tool, and watch your business flourish through well-executed promotional efforts.